The smart Trick of Plastic Injection Molding That Nobody is Discussing

Wiki Article

Plastic Injection Molding for Beginners

Table of Contents5 Easy Facts About Plastic Injection Molding ExplainedThe smart Trick of Plastic Injection Molding That Nobody is Discussing8 Easy Facts About Plastic Injection Molding ExplainedExcitement About Plastic Injection Molding

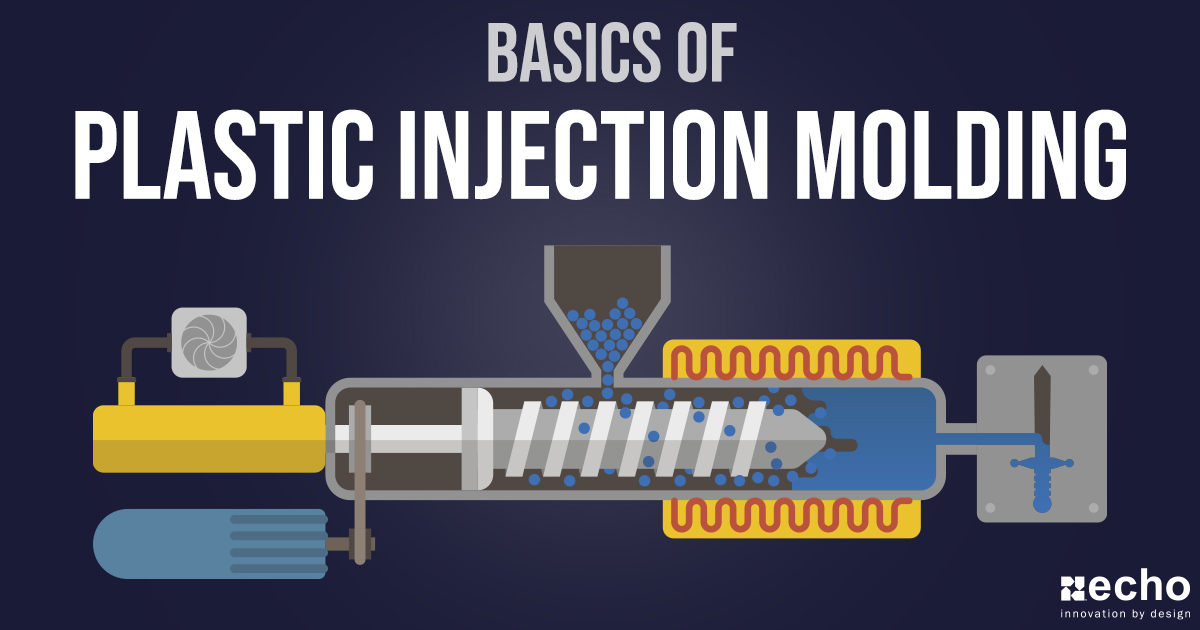

The series of occasions during the injection mould of a plastic component is called the shot moulding cycle. The cycle begins when the mould closes, adhered to by the shot of the polymer into the mould tooth cavity. As soon as the cavity is filled up, a holding stress is kept to compensate for material shrinking.

This creates the screw to retract as the next shot is prepared. Once the part is sufficiently trendy, the mould opens up as well as the part is ejected.: 13 Scientific versus standard moulding [modify] Traditionally, the injection section of the moulding procedure was done at one constant pressure to fill up as well as load the tooth cavity.

As soon as the tooth cavity is 98% full, the maker changes from velocity control to stress control, where the cavity is "loaded out" at a continuous pressure, where adequate velocity to get to desired stress is needed. This allows workers regulate part measurements to within thousandths of an inch or much better. Like all commercial processes, shot molding can create mistaken parts, also in toys.

Things about Plastic Injection Molding

Tests are frequently done prior to complete production runs in an effort to predict flaws and also determine the suitable specs to make use of in the shot process.: 180 When filling a new or unfamiliar mould for the very first time, where shot dimension for that mould is unknown, a technician/tool setter might carry out a dry run before a full manufacturing run. plastic injection molding.Once they attain this, they apply a percentage of holding stress and boost holding time until gate freeze off (solidification time) has happened. Entrance freeze off time can be figured out by raising the hold time, and afterwards considering the component. plastic injection molding. When the weight of the component does not transform, eviction has actually iced up and also say goodbye to product is infused right into the part.

, really harmful if the component is being made use of for a security essential application as the material has extremely little toughness when delaminated as the products can not bond. Excess product in thin layer surpassing regular part geometry Mould is over jam-packed or parting line on the device is harmed, too much injection speed/material infused, securing force as well reduced.

The Greatest Guide To Plastic Injection Molding

Loading also quick, not enabling the edges of the part to establish up. Additionally mould might be out of registration (when both fifty percents do not centre appropriately as well as part walls are not the very same density). The given details is the typical understanding, Adjustment: The Lack of pack (not holding) stress (pack pressure is used to load out even though is the part throughout the holding time).

Simply put, as the part reduces the material divided from itself as there was not sufficient material in the tooth cavity. Deep space could take place at any type of area or the component is not limited by the density however by the resin circulation and thermal conductivity, yet it is a lot more likely to take place at thicker areas like ribs or employers.

Knit line/ Blend line/ Transfer line Discoloured line where two circulation fronts meet Mould or worldly temperatures established too reduced (the material is cool when they meet, so they do not bond). Time for transition in between injection as well as transfer (to packing as well as holding) is too very early. Turning Distorted component Cooling is as well short, material is also hot, absence of cooling around the tool, wrong water temperatures (the components bow inwards towards the hot side of the device) Uneven diminishing in between areas of the component.

The Facts About Plastic Injection Molding Revealed

More about the author 125 inch wall thickness is +/- 0. The power needed for this process of shot moulding depends on several points and also varies between materials used. Below is a table from page 243 of the exact same read this article reference as previously discussed that finest highlights the features relevant to the power needed for the most commonly made use of materials.In addition to mounting examination systems on automated devices, multiple-axis robotics can remove components from the mould and also position them for further procedures. Particular instances consist of eliminating of parts from the mould right away after the parts are developed, as well as using machine vision systems. A robot holds the component after the ejector pins have been expanded to free the part from the mould.

Why is shot molding device manufacturing so reliable? What is Injection Molding?

The injection molding equipment utilizes customized molds to load them out according to specs, developing similar duplicates that can be tailored in a variety of methods. What's even more, injection molding is a very flexible process, allowing for a variety of different products and finishes, that makes it a popular option in countless industries with totally various goals as well as requirements.

Report this wiki page